Scratch-Built PT 596 Pier Display Base

By Michael Benolkin

Background

When I started building the beautiful Italeri 1/35 PT 596

kit, at that time I had envisioned building it into a waterline display base rather than keep it full-hull on a stand. That really sounded great until I reached the point in the PT 596 build where I actually needed the display base. It was time to embark upon a new adventure.

First of all, I am not skilled at working with wood. I took wood shop in high school, but that was 40 years ago! On the other hand, I’m not building a storage chest or dresser, I’m doing a “simple” display base. So what is this going to look like? I could cop out and simply do a smaller base with the PT boat at sea, but I don’t have any experience with water effects and high speed PT boats generated lots of water effects. I like dioramas and vignettes that have several models and figures on it that tell a story. In this case, I think I’ll do a pier-side diorama.

Construction

I pulled out the traditional mission planning tools from my days in flight test (bar napkin and pen) and put together a layout for this diorama (see figure one). I figured the ideal size would be three feet long by 1 foot wide. This would allow for a portion of the pier to be on the diorama along with a beachside dock where I could park a vehicle and stacks of supplies.

So for the first step, I wandered through several of the local hardware stores looking for a piece of wood that would serve as my display base. All I could find initially were two and four foot long shelves that were laminated, so any attempt at trimming the shelf to size would leave one end of the shelf revealing its MDF (particle board) roots, and also potentially screwing up the laminate near the cut. The solution needed to be a hardwood shelf. After wandering through the wood departments of several stores, I found the shelf I needed, plus some wood trim strips that would frame the display base. The store even cut the shelf to three feet for me as I don’t have the saw at home to do a perfectly square cut.

Not long after acquiring the wood, I had to go out of town, and when I returned, the wood shelf had warped! Ouch! If I had wasted any effort on this base before the warp, I would have probably tossed the whole project! Nevertheless, I was back to square one on a display base. A trip to more specialized wood supply store solved the problem. The folks explained that the ‘hardwood’ shelf I bought at another store was evidently the bottom grade of hardwood and a change of humidity did in that piece of lumber. I found a better quality wood which was evident by the grain and color, and once again the store cut its four-foot length to three feet.

Being a good cynic, I waited a few weeks after buying this new wood to see what would happen, but it remained perfectly true through several weather changes. Time to get started! This nice piece of wood was only eleven inches wide, so I lost the plausible width of a wooden sea pier. I placed the PT-596’s hull on the base and while I was going to have the dock I wanted at one end, the pier along the side of the boat was going to be only a partial structure. I needed to do some re-engineering to pull this off.

The problem is that I need to put some sort of frame around the edge of the base to dam in the clear resin I’d be using for water. If I don’t have some way to trap the resin, I’d have a mess on my hands! I was originally going to use a wood trim all the way around, but now I needed some way to support a partial pier. A quick trip to my local hobby establishment solved the problem. In the supply of balsa wood shapes they had in stock were strips of balsa 36” x 3” x ¼”. I’ll box in two sides of the base to support the pier and use the wood trim on the other two sides. I picked up a good supply of balsa wood strips for the pier and some wood dowels for the pier pilings.

With everything on hand (finally!), it was time to kick off this project. I sanded down the shelf and dressed the edges so there wouldn’t be wood splinters in my future. Next I cut the 36” x 3” planks to the lengths I needed and used white glue and clamps to mount them onto the base. White glue requires some time to dry and I could have significantly sped up this process by using cyano and Zip Kicker, but white glue is more tolerant to flexing as this project was going to get man-handled not only during construction, but also later as it finds its way to the occasional contest table.

While the glue was drying, I brought out a straight edge and pencil to draw the pier outline onto the base. I needed to account for the width of the pilings between the pier and the boat hull and I didn’t have that much room to work with. I also had to take into account the width of the wood trim that would also take away space from the hull on the base. After eyeing the section of the dock that would be ahead of the bow, I decided that I didn’t want to replicate all of that support structure under that width of pier, so I boxed that section in with the 3” wide balsa as well. With that structure worked out, I installed the wood trim around the remainder of the base. I now had a solid dam for the clear resin.

It was time to build up the pier structure. The deck of the cut-down hull was going to be around two inches above the surface. Don’t get too hung up on precise heights here as piers were anchored into the ground, but the ocean rises and falls with the tides, so the pier’s height above the water will change. If the pier was designed to support heavier vessels, you’d expect the piers to be much higher than the decks of these PT boats, but I opted for a pier that was built to support this size vessel. For this diorama, the surface of the pier was going to be a little higher than the deck of my PT boat.

I placed the hull on the display base one more time to make sure the lines were still correct, then started with the pier pilings. I cut the dowels into 3¼ inch lengths and cleaned up the ends of each dowel. Starting with the corner, I used white glue to install each dowel and placed each piling about 3½ inches apart. I used a right angle square to ensure each piling was roughly vertical.

Next, I used a two inch wide strip of wood as a jig to set the height of the pier frame. I white glued balsa strip to the backwalls of the base using the jig for height. With the strips clamped into place, I added strips at two inches to the pilings and clamped these into place as well. The pier was now ‘boxed in’.

I cut strips of balsa to replicate part of the under-structure of the pier and started the end section of pier that would mount a cargo crane. If you’ve paid attention to the lengths and angles, each of these bits of wood are identical in length, and I used a Northwest Short Lines ‘Chopper’ to achieve the precise lengths of balsa. I love it when plan finally comes together!

Before I start planking the pier, its time to do some finishing on the wood. First, I applied several coats of sanding sealer to the base and pier, then carefully sanded the surfaces. This removes more blemishes in the wood surface as well as prepares the wood for painting/staining. I applied a combination stain and polyurethane finish to the bottom and outer sides of the base. That took the better part of a day to cure

Now it is time to paint! I loaded up my trusty Iwata with a load of Tamiya Flat Black and painted the inside surfaces of the side walls as well as the areas under the pier that would be in ‘shadow’. If you’ve looked in the water around a working pier, you can rarely see the bottom with all of the stuff stirred up in the water. Since these piers were likely inside a safe cove or channel somewhere, the water is relatively shallow and full of life. Green water would do here. I started with a base coat of Tamiya Field Gray (same green as the PT boat) and then added highlights and shadows with other colors. I used flats as they dry faster and would have no effect on the water surface.

My hobby shop recommended an interesting clear resin product for this job. They had 16 ounce kits of EnviroTex Lite, which can be used to provide a ‘bullet-proof’ surface for tables and high-use wood surfaces. It is a gloss clear resin that is a two-part mix that takes equal quantities of each part to create a solid clear resin surface. I decided to give this a go. I mixed the two parts together and poured it into the base. It takes about a day to cure into a solid surface and the results were spectacular. The 16 ounces was just perfect to create a roughly ¼ inch thick surface.I bought two packages of the stuff as I want to permanently mount the hull to the display base, but since I trimmed the hull close to the waterline, I want to place the hull onto the current surface and use a thinner layer of resin to fix the hull and start adding some waves in the surface.

To mount the hull, I took a second package of the EnviroTex Lite and only mixed half the contents together. With the hull in place on the surface of the cured resin, I poured about half of that mixture into the hull. As expected, some of it oozed outside of the hull and created a wave around the PT Boat. I poured additional waves here and there that cured where they were supposed to be. Later, I'll use other materials to 'complete' the wave effects.

Oh yes, in one of my wanderings through eBay, I found an interesting metal hat pin that it several inches wide commemorating the PT boat Navy. I was originally going to put this under the surface of the water as part of the display base, but now that I have the sidewalls of the pier structure, I have mounted it on one of the outer surfaces.

After the resin had completely cured, it was time to stain the exterior surfaces of the wood. I applied MinWax in a nice rich dark shade to the surfaces and let it dry. This was covered with a gloss clear polyurethane finish which completed the outside surfaces of the display base.

I pulled out my trusty Northwest Short Lines ‘Chopper’ again and started cutting pier planking. This tool was designed for the model railroader who wanted to cut their own wooden railroad ties with a precision cut at a precise length. This is exactly what I needed for this job as I had ensured that the pier joists were parallel to their respective backwalls and I would only need two lengths (except where the planks butt around the pier pilings).

When I had enough planks cut, I ran beads of white glue along the joists mounted on the backwall and the pilings. It really didn't take too long to plank the entire pier. Amazing how easy the job can be when you have the right tools!

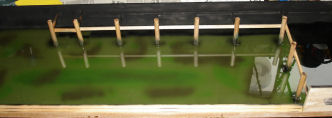

You can see the raw balsa wood planks in these images:

When everything had dried and the planks were solidly in place, I had to do something to darken the shade of that balsa wood. The solution was simple enough, I used artist oils. I mixed a combo of Burnt Sienna and Titanium White into Odorless Mineral Spirits to achieve a dark wash. I brushed the mixture onto the planks, let it sit for a few minutes, then took a rag and buffed the surface of the planks. The results were perfect. There will be further work here to weather and age the pier, but that will come after the completion of the PT-596 build. You can see that the main pier off the bow is long and wide enough to hold a cargo truck or Jeep as well as piles of supplies pierside. This too will all be done after the PT-boat itself is completed.

Conclusion

This completes the basic display base for Italeri's 1/35 PT-596 and while the project took some time, the materials were inexpensive. This may not be the layout that suits your display base, but the intent here was to show how to "think out of the box" (the kit box) to achieve a nice backdrop for a model as nice as the Italeri kit.