DML 1/48 Ta 152H-0 Kit First Look

By Michael Benolkin

| Date of Review | February 2009 | Manufacturer | DML |

|---|---|---|---|

| Subject | Ta 152H-0 | Scale | 1/48 |

| Kit Number | 5539 | Primary Media | Styrene, Photo-etch |

| Pros | Exquisite detailing | Cons | |

| Skill Level | Intermediate | MSRP (USD) | $46.95 |

First Look

|

|

|

|

|

|

|

|

Doctor Kurt Tank was the designer of the Focke Wulf Fw 190 series and put the name Focke Wulf forever in the history books. Nevertheless, Tank was given his own design team to tackle the problem of developing a high-altitude interceptor. The resources of Focke Wulf were left to production of the existing Fw 190 line.

The task at hand was to develop an interceptor that could reach higher altitudes with a combination of greater lift and more power. To counter the effects of prolonged operations at altitude, the cockpit had to be pressurized. The result was the Ta 152H, an aircraft that bears a strong resemblance to the Fw 190D series, but was in fact a completely different aircraft. The wingspan alone was significantly greater.

Here is one of Trimaster's greatest kits, the Ta-152H. This kit, along with the others in the series, was way ahead of its time in terms of detail and molding technology. This kit is still the best injection-molded Ta 152 in any scale. The upcoming Pacific Coast Models 1/32 Ta 152 may just assume the title of best in any scale, we shall see.

This was the ninth kit in Trimaster's line-up, but the first one released when DML acquired the molds. Nobody has matched the Trimaster kit to date (in styrene).

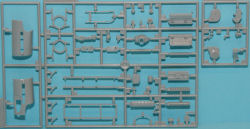

The kit is molded in light gray styrene and presented on four parts trees, plus a small tree containing the clear windscreen, canopy, gunsight, and light lenses. Two small frets of photo-etch are included containing seatbelts/harness, rear cockpit deck, canopy hood locks, antennas, and more.

While most aircraft kits start off in the cockpit, this one starts under the cowling. The first task is to assemble the Jumo 213E engine that is quite a detailed model in its own right. You might wonder why you'd build up a detailed engine? Two reasons actually.

- Tank's long-nose fighters did not have a completely enclosed main wheel well. This allowed the engine to draw more air through the cowling when the landing gear was down. Since you're likely to build this kit gear-down, you'll want to see more than an empty plastic shell up where the engine would be

- While you see that the nose is molded closed-up, you'll also note that there are a pair of cowling access panels molded separately in the third frame. You have the option of cutting away the molded-on doors and replacing these with the provided doors in the open position to display that nice-looking engine

The cockpit is next, and like the Focke Wulfs that preceded this kit, the detailing is very nice! The instrument panel is molded with nice relief to make painting easy, but the kit was released long before photo-etched instrument panels with acetate instruments. If you prefer this sort of detail, Eduard released a detail set (48224) that will help you along.

As I recall, some of the details in the Trimaster version of this kit were actually cast in white metal, but DML recreated these parts in styrene for their subsequent releases.

Markings are provided for the primary kit subject, Green 1 of JG.301 as flown by Oberfeldwebel Willi Reschke. In addition, an alternative set of markings are provided for Green 9, though there is no mention of this aircraft in the instructions.

The instructions are nicely illustrated and clearly show the colors for all of the parts using Gunze Sangyo color numbers, though a table is included to translate those colors into generic color names.

This kit has been reissued a few times but is currently available in this edition produced for the 2008 Dragon Expo. I'm looking forward to another upcoming release from DML. Way back when, Trimaster released a limited edition Ta 152C in this 1/48 series which was a combination of styrene and resin parts for the airframe. DML has announced that they are releasing the Ta 152C and I'm hopeful that this will replace the resin parts with styrene tooling. We shall see.