Panda-Hobby 1/35 9A310M1 TELAR w/9M38M of 9K37M BUK-M1 Kit Build Review

By Michael Benolkin

| Date of Review | July 2019 | Manufacturer | Panda-Hobby |

|---|---|---|---|

| Subject | 9A310M1 TELAR w/9M38M of 9K37M BUK-M1 | Scale | 1/35 |

| Kit Number | 35033 | Primary Media | Styrene, Photo-Etch, White Metal |

| Pros | Nice details | Cons | See text |

| Skill Level | Experienced | MSRP (USD) | $69.95 |

Build Review

For a look at this kit straight out of the box, look here.

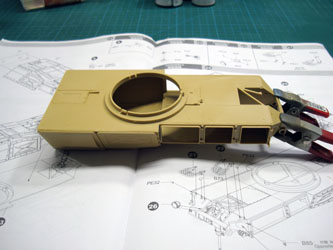

As with any armor build, construction of this kit starts with the underside of the hull, but I wanted to jump ahead and assess the overall fit of this model. To my pleasant surprise, Step 1 wanted several flashed-over holes drilled out before the upper and lower hull halves are assembled in Step 2. After some dry-fitting, I glued the halves together and clamped the assembly while I jumped ahead to the turret halve, which go together in Step 24.

The hull and turret assemblies are rock-solid and snap together as well. Now I'm ready to dive into the details...

Steps 3-10 cover the details on the underside as well as many of the details on the upper surfaces of the hull. I elected not to glue the wheels or sprockets into place until after the primer has been applied (which is coming soon). One note here the suspension arms identified in Step 8 indicate that on each side of the hull, part E2 goes up front, part E4 goes to the rear, and the remaining four holes receive part E3. The problem here is that this required eight parts E3 and only six are provided. The good news is that with the exception of small details on the suspension arms, parts E2, E3, and E4 are identical, so I used parts E4 on the rear two holes on each side, using all six parts E3 in the remaining six holes. A few other tips - I didn't glue the suspension arms until they were all in place and I had gently twisted them as far down as they could go. I then rested the hull on its suspension arms and gently pushed down on the hull, then glued the arms into place. Now the hull is resting flat with all of the arms on the work surface. When the wheels go on, they too will rest flat on the work surface. While I will also glue the drive sprockets into place after primer is applied, I will wait on the return roller and the tensioner arms (parts E46) until after the track is installed. Leaving these loose will allow me to tension the track once they're ready for installation.

Steps 11-13 assemble the driver hatches, Step 14 covers the tow cable, and Steps 15-16 cover the headlamps. In the case of the hatches, I simply glued D12 to D11 as I don't intend to display these hatches open since there is no interior. Here is where I could have had some frustration. The hinge parts 44 and 45 are shown in the instructions going to the wrong hatches. These are reversed. Since I test-fit each part with the understanding that the part numbers could be off, I rarely run into problems, though this does slow down the assembly process. Oh yes, the instructions identify the slit lamp housings as part B14 (should be B15) while the 'normal' headlamps are identified as parts B15 (should be B14).

Step 16 is the slit lamp and the instructions show a lens (part GP2) going onto the lamp (part B15). There isn't a lens visible since this is a slit lamp, so omit part GP2 on both slit lamps.

Step 15 builds up three 'normal' headlamps, two for the left side, one for the right. The normal lights are mounted outboard of the slit lamps and have normal silver reflectors behind the lenses. One of the headlamps mounts on the inboard side of the left slit lamp, and it has an infrared (black) lens. These details aren't mentioned in the instructions. I'll add the lenses after painting.

Steps 17-21 finish out the small details on the hull. I have a few more to add, but first, I need primer so I can add the photo-etched grills and the road wheels.

Taking my time and test-fitting the parts makes the process straightforward (sounds like common sense), but aside from some misidentified parts in the instructions, I am impressed with the fit of the kit so far.

Steps 22-23 covers the assembly of the hydraulic ram that elevates the four missile rails atop the TELAR. Looking at the instructions, the assembly looks easy enough, but I spent quite a bit of time here as the two mounting arms (B32 and B33) that are positioned on either side of the hydraulic ram cylinder (B95) would not get properly oriented to mount to the cross-beam (B27) and all of that to the underside of the turret (A6). Fortunately, I had glued the turret halves together which made the process easier once I figured out the illusion that was hampering my progress. The hydraulic cylinder itself is a nice bit of engineering as it is one-piece and slide-molded so the interior of the cylinder is hollow to full depth so that the ram (B50) will articulate freely. I'm not sure why I had a problem with this step, but it wasn't anything that an adult beverage wouldn't fix.

As I mentioned above, Step 24 is where the upper and lower halves of the turret come together. If you do what I did and assemble them early, the only caution is to mount part C39 to the rear of the turret before adding subassembly 'A' to avoid interference. Otherwise, the process of assembly in Steps 25-33 are simply assembling and adding the small details.

Step 25 is supposed to assemble three parts that mount to the left-rear corner of the turret. The problem here is while part E18 mounted to B86, part E40 is supposed to mount to E18, but on all six E trees in the kit, there is a marker for part E40, but no part there. I skipped part E40 and moved on.

The radome goes together in Step 29 and I simply dry-fitted it to the front of the turret until painting was completed.

In subassembly 'B' in Step 33, we build the same three-piece subassembly as Step 25, except that while the instructions have you use E18 mounted to B86, this should be E18 mounted to B87. Since there is no part E40, I mounted this subassembly to the right-rear of the turret.

I skipped Step 34 (tracking camera) to get the remainder of the small parts onto the turret in Step 35 so I could wrap-up the incremental primer (black) as you can see below and start on the camouflage.

I didn't want a plain Russian green TELAR, and the color profiles included in the kit offered some interesting options. Below is my first shot at that using a four-color scheme, but the result didn't look right to my eye as I had free-handed the colors. Masking the TELAR isn't an option given all of the small parts all over the hull and turret, so time for Plan B.

With Plan B, the idea was to add a black or dark gray demarcation between colors, and while it looks a little better, I feel the need for some precision touch-ups. I am glad I waited on the launch rail assembly as this would have complicated the painting process.

Touch-ups are competed and the demarcation lines are no longer prominent. The tracking camera assembly from Step 34 was assembled and installed as well. There were a couple of small glitches here. First, the camera lens cover is identified as part B5, but that was the arm that swings the cover up and away when the camera is in use. Be careful here as one end of B5 was short-shot on my kit and I had to do some reshaping of the blob at one end of the part to resemble the hinge. I still needed the lens cover and a quick survey of the parts trees found the part to be B56.

Moving on to Step 36, this is the assembly of the antenna mast, and the way this subassembly is laid out, it looks like it was intended to be movable to erect when the missile launchers elevated. Skipping Steps 37-38 for the moment, I wanted to get the missile launchers (Steps 39-40) assembled to see how these were going to work with that antenna mast. Following the instructions, I assembled the two lift arms, then tried to make sense of the triangular blocks that mount to either side of the lift arms. These blocks house the interface to the missiles and before you glue the triangular blocks together, you insert a half-cylinder (part E17) inside. I would suggest gluing part E57 to E17 for each of the four assemblies. which will help with alignment of the parts inside the triangular blocks. The triangular blocks are identified as parts D27 and D28, but on the parts trees, they're both labeled D26, along with the real D26 used earlier. It isn't difficult, but you'll have to eyeball the assemblies according to the drawings and ignore the part numbers here.

As you mount the triangular blocks onto the lift arms, you'll find another set of challenges - there are pins where there should be holes. After dry-fitting the parts, I removed on the offending pins, drilled a hole in its place, and the parts go together. On the front end of each lift arm, there are a pair of cradle subassemblies that support the missiles, and I found that in the instructions, part D14 should be D13 and vice versa. The cap on the end of the lift arms (part E6) that holds the two cradles on each arm is missing a hole on one side which will need to be drilled so the subassembly will fit properly. The photo below shows the antenna subassembly with the two lift arms/missile racks and a cross-arm, all assembled and painted, it was time for an adult beverage after this session.

The kit provides two different versions of the SA-11 missile, four of each type. I initially wanted two of each on this TELAR as I've seen photos of such loads online and thought it would look interesting. Steps 37-38 cover assembly of both missile types, but after assembling the fuselages, I wanted to paint the airframes before masking and painting the fins, radomes, and motors. In this photo, I have the holes molded onto one side of each missile plugged into the interfaces (parts e57).

With the fins, radomes and motors painted, I began to assemble the missiles. Much to my surprise, the main fins for the missile in Step 37 do not fit onto the airframe. I tried opening the slots on the airframes and thinning the tabs on the fins, but all I was doing was messing up the paint. I decided to set these aside and use the Step 38 missiles alone. I could have built the other two Step 38 missiles, but leaving off two of the missiles shows off more details underneath.

Steps 41-42 have you mount the missiles onto the lift arms/launchers and while this would make this assembly easier, I am glad I waited. Since I wanted to see if this could be built with movable lift arms and have the antenna erect with the arms, I didn't want the missiles in the way. This turned out to be a blessing because there's another glitch in the model in Step 43. The right lift arm plugs into the hinge on the right-rear of the turret, but the left arm doesn't fit at all. It took quite a bit of filing the hinge pin and hole on the left side to get a fit, and it wasn't going to be movable at best. I glued the left side in followed by the right side, added the connecting beam between the lift arms, and connected the hydraulic ram to the beam. The antenna subassembly mounts between the two lift arm assemblies, and I left it in the stowed position.

Note that Step 43 assembles the lift arms/launchers onto the turret in the stowed (down) position while Step 44 assembled them in the ready (up) position. The diagram in Step 44 mounts that cross-beam on the launchers onto the hydraulic ram like in Step 43, but it doesn't mount the rear hinges to the rear of the turret. This kit will build the TELAR in the ready-to-launch position but using the same process for the left lift arm above, plug the lift arms into the turret's hinges.

So here is the TELAR sans track. Now to set this aside and figure out the track.

As I mentioned in my first-look of this kit, Panda Hobby includes a small box with metal track links and pins. In theory, push the links together and insert the pin. In practice however, the links were fighting me every step of the way. Using a variety of tools, i attempted to find the right combination of steps to speed things along, but at best, I could only get one link added every five minutes or so. Given that there are over 100 links per run, this was going to take a while. Over the last week, I'd take some time to sit down and work through the track link challenge. With the help of my high-power Optivisor lenses, I found the problem and the solution. Each link as its own random bit of mold flash, though they're probably not random as I bet I could sort through the links to see how many molds were used to cast these links. Each mold will replicate the same flash bit with each link, but as all of these links are mixed together, the flashing seems random.

In any case, the solution was the same, take a nice square hobby file and file all of the mating surfaces on each link. Unlike a flat file (which wasn't working for me), the square file will get into corners and work two surfaces at a time. Once I've filed each link, I would use the tip of an X-Acto blade to clear out the hole openings for the track link pin. Slide the cleaned link into place, and if it fits without any problems, insert a track pin, push it through about half-way, then flip the track onto its side and I used a small mallet to push the pin all the way through. While this still takes a little time, I'm able to do about 10 links now in the time it took to do one at the start. The photo below was taken just after I broke the code on assembling these links and I'm nearing 60 links in one run and 10 in the other.

One suggestion to speed things along, Panda Hobby provides the links and pins in the same box. You'll want to get the pins into a separate container, but before you waste time fishing them out of the box, pour the box contents into a pile on your bench and use a magnet. The track links are not magnetic, the pins are magnetic. In under a minute, you'll have the relevant parts separated.

To be concluded - stay tuned

My sincere thanks to Panda-Hobby for the review sample.