FM 1/48 BR.1050 Alize Build Review

By Fotios Rouch

| Date of Review | June 2006 | Manufacturer | Fonderie Miniature |

|---|---|---|---|

| Subject | Breguet BR.1050 Alize | Scale | 1/48 |

| Kit Number | 6041 | Primary Media | Styrene, Resin, White Metal, Photo Etch, Vac |

| Pros | Nicely detailed kit | Cons | Flash clean-up required |

| Skill Level | Advanced | MSRP (USD) | TBA |

Build Review

For a preview of the kit click here.

The FM Alize build process started as usual with washing all the parts, resin and plastic alike with very warm water and 409 cleaner.The sprues with the parts were allowed to air dry and the next day I started the task of removing the plastic from sprues. The gates are thick. The plastic parts are often surrounded by heavy flash. I used wire cutters to get the parts off the sprues and a heavy sanding stick to remove the remaining plastic from the gates.After I cut off all the plastic parts from the sprues and after I was satisfied with the cleanup, I turned my attention to the resin parts. There is a lot of excess resin to be removed behind the parts. I used a Dremel tool and a sanding drum to save time.

I started working first on the plastic. I have to say that a lot of detail is present on the interior plastic parts and it shows well with some dry-brushing and shading. I used Xtracolor "Sable" from their French color line which looked just right to my eyes for the yellowish color that the French use in the bomb bays and landing gear bays of many French Navy planes. I used a slightly darker brownish hue to accent some areas and make the bays more visually appealing. In this picture you can see the detail provided for the main ordinance bay and the three landing gear bays. I have added no details of my own.

The cockpit is done in resin mostly with some plastic pieces and metal seats. The seat belt are provided in photo-etch. I used Testors "Interior Gray" for the floor and side walls. I highlighted the details with "Gunship Gray". I used tinny drops of Future to give some sparkle to the instrument gauges. FM provides also the overhead instrument console as a separate piece to be glued onto the vacuform canopy. A metal fire extinguisher is provided in white metal which I painted red and three oxygen bottle are provided on the side wall which I chose to paint "Apple Green" as per the general tradition. I hope the French do not have some different ideas on that!

The next stage is to make the front wheel well, the cockpit, the bomb bay, the radar bay and the tail hook bay all fit in the very thick plastic fuselage parts. Basic test fitting showed that this is going to be a very tough act.

The next installment will cover the closing of the fuselage. If this happens without any attrition then the rest should be easy. Maybe.

After the main subassemblies were completed it was time to turn my attention to putting all that inside the fuselage. Initial test fitting had shown that not a single subassembly would even remotely fit inside the fuselage or the wings.

Since this was not supposed to be an overnight build I left it well enough alone and spent the weekend going to Halloween parties for adults and children...

Refreshed, I returned to this crazy project which quite possibly is the most stubborn plastic kit I ever built.

First step was to sand down the fuselage mating surfaces. I treated the kit like a vacform kit so to speak. I laid down some coarse sand paper, added some water and with circular motions I sanded down all the imperfections and also thinned out the tail trailing edge. the trailing edge smoothed out well and the excess plastic flash just fell off.

After the fuselage sides were cleaned up I did some preliminary test fitting to see where I stood with incorporating the interior subassemblies. The cockpit did not fit at all. I started thinking that the team that did the fuselage parts was prohibited from lending the fuselage pieces to the team that did the cockpit parts. It could be really that the airframe team and the details team worked off the scale plans assuming practically zero thickness on the parts.

Yet the parts come in the box very thick and it is up to the modeler to thin them down. How much thinning is necessary? I had to go down to paper thin for the fuselage and the cockpit side walls. I used my Dremel tool and dug the plastic up. I used a pencil to draw outlines of where the subassemblies were supposed to fit. Naturally, in this now pressure kit you do not get any locating pins for all this interior detail parts. I kept test fitting each subassembly until I was happy with all the interior parts and how they fit.

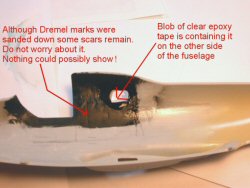

After everything looked like it could be glued in place I started sanding down the heavy scars that the Dremel tool left. I knew fully well that the scars would not show through the cockpit windows under their black interior paint even if using a "pen light".

After the cockpit wall paint was dry, I mixed some clear epoxy and put a blob of it where the side windows are. The kit provides vacform pieces but I was not going to fight with them and making them fit in the provided openings when clear epoxy is so forgiving and so shinny!

I started gluing the fuselage from the cockpit area hump and went forward. Once dry, I glued the rear fuselage portion and the tail. Lots of clips and tape were used to keep everything together until the glue would dry. There were many little areas of concern where there were gaps and many imperfections. No worries, all that will be dealt with later.

Once the top portion of the fuselage was secure I started work on the bottom portion. I knew this area would be more work and I needed the structural rigidity of the top fuselage to help me with battling closing up the bottom portion. The problem is that the plastic is uneven or there is not enough of it! Lots of superglue was used to keep it all together. Lots of scratch plastic will be used here to fill the gaps. You can see from the two pictures what I mean.

As all that was drying, the wing parts were sanded down to smooth them out and to get thinner trailing edges. They went together with the help of clips just to make sure that no gaps would be left behind. The next step was to put together the wing pods that house the main landing gear. More trouble is foreseen to be had here as the pods fit badly and the landing gear wheel wells do not fit inside them at all!

Well, as it was expected, the wing pods did not fit well when test fitted to the wings. The wing pods did not fit at all if the wheel wells were incorporated in the test fitting. Out came the Dremel tool again and the top and bottom parts of the wings were hollowed out until almost transparent. The wheel well was also thinned out at the outer walls and was test fitted numerous times until it was ensured that the wing could be closed up. Everything was glued together and secured for the 24 hour cure time.

In the mean time I glued the tail wings on the fuselage and was shocked by the huge gaps left behind. The tail wings are just not engineered to fit to the fuselage and this is not just because of the plastic molding being poor. They just do not have the contours to fit. I helped the resulting gaps with super glue and accelerator.When all was dry, I laid down generous amounts of 3M Acryl Red which by the way dries faster than 3M Acryl Blue. All joints were treated with putty both as a means to fill the gaps and mismatches and also as a means to recontour certain uneven areas.

The next step after all the putty dried up was to carefully sand it down with water and sanding sticks. Speaking of sanding sticks, I have to tell you what I use. I go to a beauty-shop supply store. They have tons of sanding sticks (nail files) there in all varieties. Some are combination nail files with up to three different grade grits on them. They are also padded so they can file and polish human nails without flat spotting them. All are very reasonably priced because they move them in volume. Try them and you might find them very useful. Also you cannot beat the look on the beauty supply store ladies faces when you check out with a bunch of girlie stuff and they have no clue what you need them for! The sanding sticks did their job nicely again and the wing pods shaped up well. After the sanding process is completed I will spray the parts with Mr. Surfacer 500 and then inspect for areas that need more putty.

Another area I noticed that needed attention was the fuselage area where the wings attach. The way the kit is designed, there is no depth for the wing to fit it. Use your Dremel and deepen the area. Also sand down the corresponding area on the wing so it can achieve a snug and flush fit. The next step will also involve putting on the main wings and priming the whole model to see where the putty job was inadequate. Then rescribing and re-riveting will have to follow to restore the damaged areas.

The next step was to attach the wings to the fuselage.

The fit was dismal and only notional with the wings barely touching the fuselage in all the proper places. On top of that it was important to have the wings attached to the fuselage at 5° angle. I made a template out of cardboard to help me dial the proper angle and super-glued the wings to the fuselage one at a time. The gaps left behind were big and the only way to deal with them was to add styrene strips and more super glue. I hit the super glue with accelerator and sanded the joints down some more. In the end, many layers of 3M Acryl Blue, Green and Red were used to get a smooth surface. The bottom side was the worst as lots of detail was lost and would need lots of rescribing.

After all the sanding was done I masked the interior and the side windows and primed the whole model with automotive primer. I polished the whole model and rescribed all the lost panel lines. One more layer of Mr. Surfacer 1000 was needed to complete the job.

It was no surprise that more putty was needed here and there as imperfections showed after polishing the fine primer. I decided to putty the blemishes and continue with adding the provided metal detail parts and the vacform canopy. The vac canopy did not fit very well and I had to use fine putty to blend it in.

The side turboprop exhaust base was added and puttied in as well as the side fuel dumps and the small hump behind the canopy.

As I was studying some very nice photos I found on the web I realized that the latest variant of the Alize that I am modeling has more and different types of antennas than what is found in the kit. The antennas are simple to make from stretched sprue and plastic stock. The little dome antenna behind the photo-etch blade antenna was fashioned out of thin plastic card and a rounded off circular piece of styrene.

Then the model was flipped over so the metal flap support actuators could be added. The soft metal parts need some minor clean-up but the locating pins are thick and the wings have only small indentations that are not sufficient to accommodate the metal parts. I decided to use an x-acto knife to drill out and widen the holes.

The model was then airbrushed with Humbrol Azure Blue147 and Humbrol Light Gray 156 (with an added touch of blue to match the photos). I used the instructions of the Mach II Alize for the color choices since my FM kit did not include any info that I could locate. After the top surface paint was dry I masked it with Tamiya tape in preparation for the under surface paint.

The underside of the model was masked with Tamiya tape and moistened paper was used in the various cavities.

The model was left to dry overnight and the masking tape was removed. I realized later that I have to respray the azure blue paint so it wraps around the bottom of the fuselage. I will do that after I attach the small photoetch parts around the rudder and the bottom surface of the wings.

The next step in the build was to attach the landing gear. You need to trim and clean up the soft metal parts and then do a lot of dry fitting before you commit anything to super glue. The front landing gear went in ok and was easy to secure in place. The only thing missing from it is the three attitude approach lights. I used thin styrene stock and drilled three holes to represent the lights and then glued it in place. The main landing gear need more attention and fine-tuning. Experiment with swapping left to right main gear oleos until you get them to look just right and vertical to ground.

As I was flipping the model and checking out the gear I heard a noise coming from the inside of the cockpit. I knew something had come off but the clear parts were masked and I could only imagine the damage that was being done.

Once the gear was done I shifted my attention to the arresting hook. I chose to drill some holes in the soft metal as per the photos on various French websites. It does a lot for the look of the hook. I also painted it a shade off the bottom camo color to make it look a bit different and add some depth to it.

Next thing I did was to work on the nav lights. I just could not stand leaving them alone and just painting them to the appropriate color. I decided that it was time for surgery! I heated some clear plastic stock and stretch formed over the wing tips. I carefully cut it around the wing tip light area and then I used a fine razor saw to remove the tip of the wing. I painted the inside of the nav light area the same Buff color that used for the bay and the wheel wells. I used colored resin clear stock from my trusty Cutting Edge set and then I glued the carefully trimmed vac corner pieces I vacuformed earlier. I like to use watch glue because it dries clear and does not mar the plastic.

The noise I kept hearing from the cockpit was driving me crazy so I decided to see what was the deal.

I sprayed Future clear floor vinyl all over the model and let it dry for a few hours. I then carefully pealed the masking tape from the canopy windows to reveal a loose pilot's seat! This seat is made of soft metal and it is heavy. Well, as I was working the model it came loose and banged around enough to scratch the side window and do who knows what other damage. The problem was pretty bad. I decided that it was time for yet another surgery. I had to cut the vac window out and see if I could save the model. I used Dymo label tape all around the window frame with the intend to cut it out to get to the seat.

I used fresh x-acto blade and slowly ran it around the frame until I got the vac window off. I extracted the window and the seat and the missing seat belt.It was time to use the extra vac canopy and remove the side window. After the side window was cut out and dipped in future I painted it and let it dry. The pilot's seat was repaired and super glued in place once more. The new side window was now glued in the opened position and it did not look bad at all! It just gave a look to the model that I did not plan on! Oh, and by the way, as I was messing around with cutting the side window I broke the soft metal front landing gear which I glued in a deflected angle just to help the look of the model.

After that entire ordeal was over I decided to do the photoetch parts. This took a while since I had to drill new holes for some of the parts.

The model was getting closer to completion and this was giving me the extra drive I needed.

I added the pitot tubes and the other necessary antennas to the leading edge of the wings keeping mind that they are all angled down as per the pictures of the real thing.

I used again my wife's long hair to the antenna wire and it looked quite good after a coat of black paint. (Sorry, wife's hair is not for sale!).

After all assembly was done it was time for the decals. If you have the Mach II kit look no further. The decals are the same. The interesting thing is that the Mach II kit has nice instructions for the decal placement but the FM kit I got did not! Maybe they were supposed on the few blank instruction sheets I received.

The decals were thick and MicroSet or MicroSol did little to help.

In the end the model was airbrushed with Testors semi-gloss varnish and left to dry for the night.

Some small touches were done with pastel paints and brush. I chose to represent my Alize in good shape like in the pictures shown in World Air Power.

This was a bit of a challenging build.

My personal opinion is that this was a pretty good master that would have been done fine justice if it was all done in resin. Done in plastic maybe helped with sales for FM but did little for the kit. Then a again I love resin and maybe I am biased.

I recommend the kit to modelers that have some experience with resin and limited run plastic and are not afraid of spending many hours on one kit with fitting and trimming and adjusting. It will be worth it in the end.

Now, I have an MS 472 and an MS 475 Vanneau not to mention the F-11 that are begging for an article.....