AFV Club 1/35 M548 Gun Truck Build Review

By Michael Benolkin

| Date of Review | September 2006 | Manufacturer | AFV Club |

|---|---|---|---|

| Subject | M548 Gun Truck | Scale | 1/35 |

| Kit Number | 35S32 | Primary Media | Styrene/Resin/Photo-Etch |

| Pros | Can be built as a cargo carrier, or a Vietnam-era gun truck | Cons | Requires a little extra effort to assure that parts fit correctly |

| Skill Level | Intermediate | MSRP (USD) | $47.98 |

Background

The M548 is an unarmored, fully tracked cargo carrier that is based upon the FMC M113 chassis and has a six-ton cargo capacity. Its 212 horsepower engine gives the M548 quite a bit of off-road mobility to get supplies out to where the troops are located.

Like the M113, the M548 is air transportable by the C-130 as well the C-141, C-17, and C-5. In 1994, the M548 was upgraded to the M548A3 standard with the installation of a new 275 horsepower powerpack and new transmission.

Unlike the M113, the M548 is a convertible top vehicle providing excellent all-round visibility. In the elements, a soft-top can be erected to provide some cover for the crew, and a frame can also be erected over the cab to provide a gun ring capable of mounting a 50 caliber machine gun for self-defense.

The Kit

For a look at the kit out of the box, take a look here.

Construction

I made the assertion that this kit looked like a simple build, but I hadn't decided which direction to take - Vietnam gun truck or more-recent cargo truck. I figured that I'd make the call when I got to the appropriate step. Starting from the beginning...

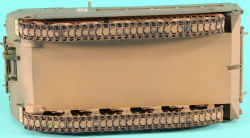

Step 1 - I assembled the road wheels, drive sprockets and return rollers as indicated. This is where I first noticed a bit of flash on the wheel rims and a few other areas. I cleaned these up with the sprue attachment points.

Step 2 - The road wheels and return rollers go straight onto the hull. The drive sprockets are mounted to the transmission bulges that go onto the hull in this step, but the openings in the side of the hull need a bit of work to get the transmission covers to fit.

Step 3 - The fuel filler insert is installed in the left rear side of the hull, followed by the fender well extensions for the interior of the cargo compartment. On the front end, I installed the recessed steps in the forward inside of the hull. The fuel filler insert needs some trimming to fit. This is the point where I start a more diligent dry-fit routine with all subsequent parts.

Step 4 - The cargo bed insert is installed along with the forward bulkhead that separates the cargo compartment from the engine housing. This is one place where dry-fitting the bulkhead and cargo bed payed dividends as the parts could get skewed if you're not careful and you'd have more fit problems later. The lower tailgate is hinged and is supposed to be positionable, but with the upper tailgate in place, it doesn't make sense to mess with the hinges on the lower tailgate. I simply glues both into place.

Step 5 - The cab interior is assembled and set aside. I left out the driver's seat and control levers until I was ready for painting.

Step 6 - The engine deck is assembled here, but I waited on installing the photo-etched screens and the intake/exhaust stacks until after the first coat of paint.

Step 7 - The cab interior slips into the front-end of the hull. If you have the recessed steps properly placed, then the interior slides over them with no problem. The bulkhead barely visible behind the seats and the cargo bay forward bulkhead make up the front and rear walls of the engine compartment, respectively. The engine deck sits atop both and completes the compartment. In this step, you also add the instrument panel and throttle quadrant to the inside of the hull front part.

Step 8 - You add all of the pioneering tools and lights to the hull front end, but I opted to leave these off until the end.

Step 9 - If all is well, the hull front fits snugly against the hull and you have a completed hull. All was not well, the hull front did not want to fit, so I opted for the nuclear option - I clamped the part onto the front of the hull, used lots of liquid cement from the inside of the cab, and set the whole thing aside for the night. When I unclamped the assembled hull in the morning, most of the edges had settled down, but it was time to pull out the Gunze Sanyo Mr. Dissolved Putty and treat the seams and some sink marks in various places around the hull.

Painting

Now that the basic hull is assembled, I gave the assembly a good washing and let it air dry. The first coat of paint was black. I decided to give Vallejo Model Air acrylics a try on this project, so I used their flat black as the base coat. When this was dry (and it doesn't take long), I inspected the hull for any tell-tale problems that need more putty. As the saying goes, the hull was good enough for government work. I was impressed with the black as it was flat, but it was as smooth as a gloss coat. If you shoot some of the more popular enamels, you know how rough a flat finish can be.

The next color shot was Vallejo's Field Green. The upper hull, cab interior, and cargo compartment were given a good coating. The Field Green comes out of the airbrush a bit bright and had me concerned that I had the wrong color, but when it dried, the color darkened back up to where it should be.

Next was the lower hull and wheels. Whichever version of the M548 I was building, it was going to be depicted in the field with a coat of mud and dirt. For the job, I selected Gunze Sangyo's RLM 79 Sandy Brown.

More Assembly

With the basic hull in the colors I needed, it was time to resume the assembly. After each logical step in assembly, I would touch up the area with the Field Green or Sandy Brown, as applicable. For this phase of the job, I am using my new Skybow 150 double-action airbrush. This has a very fine spray pattern and no paint cup. You put a few drops of paint into a recess on the top of the airbrush and hit the area with a very controlled touch-up. Clean-up of this airbrush is fast and sweet!

Step 10 - Assembling the 50 caliber machine guns. It was time to make the decision. I opted for the more contemporary cargo truck and will save the quad-mounted gun unit for a future project. I assembled the single gun per the instructions, then painted and gave it a good wash with black oils.

Steps 11-18 - Quad mount steps. I could skip these for this build.

Step 19 - The windshield and side window frames needed quite a bit of clean-up from flash and mold stubs. I pre-painted the window frames before installing the transparent parts. With the clear parts installed, I masked and painted the frame on the clear windshield part as some of the frame detailing was molded into the clear instead of the frame. With was quickly dealt with using cut-up Post-It notes for masks and the Skybow airbrush.

Step 20 - This step assembles the gun ring that mounts above the cab. The kit provides two different styled rings to represent an early Vietnam era ring and a more contemporary version. I opted for the latter.

Step 21 - This step deals with the supports to mount the gun ring over the cab. The part that has the rear supports required a lot of trimming and fitting before it would fit. With everything fitting as it should, I put the supports into place and mounted the gun ring.

Catch-up Details - We're nearing the end and it is time to add the details skipped earlier. I added all of the pioneering tools to the front end of the truck as well as the tow cable on the rear tailgate. The photo-etched engine grilles were cyanoed into place and the full-length exhaust and intake pipes added. I drilled out the air openings on top of the intake pipe before installation.

Step 22 - The windshield wipers were installed per the instructions. I pre-painted the track RLM 79 and installed them. I pre-painted the skirts with Field Green and Black and added them to the sides of the hull.

Step 23 - Gun truck final assembly - skipped.

Step 24 - This is the cargo load for the vehicle - a variety of 30 and 50 caliber ammo cans. These were assembled per the instructions, painted, and mounted in the cargo bay.

Markings

I opted to make this a vehicle on an ammo resupply run as part of the Bosnian peace-keeping mission. I applied two decals directly to the paint without using a gloss coat or preparation of any sort. The paint was as good as it appears - there was no silvering of the decals. I applied the remainder of the vehicle's tactical markings. One word of caution - the AFV decals are VERY brittle. I had one decal, a placard for the driver's door, disintegrate beyond the ability to salvage. Most of the others had broken up in into at least 2-3 pieces, but these were manipulated back into place on the model and left to dry.

Final Steps

As I said earlier, this was going to be a vehicle that has been in a little mud and lots of dust. I created a thin mixture of RLM 79 and applied a thin spray over the vehicle to accumulate dirt and dust. This blended the decals into the model. I applied a little thicker layers as I got closer to the ground. When this had dried, I washed the road wheels, track, and basically all of the details with black oils and left it to dry.

Conclusions

This wasn't a bad project, though it did take a little longer than I'd estimated. As the saying goes, the devil is in the details. Taking a little extra time to work the details made the difference on this project and I'm rather pleased with the result. I did opt not to cement the windshield/soft-top assembly to the cab, but I may change my mind later.

Is this a difficult project? Not at all. It does take a little more work to get everything to fit properly. What's nice is that AFV does tackle subjects overlooked by other manufacturers and this one is definitely one of them.